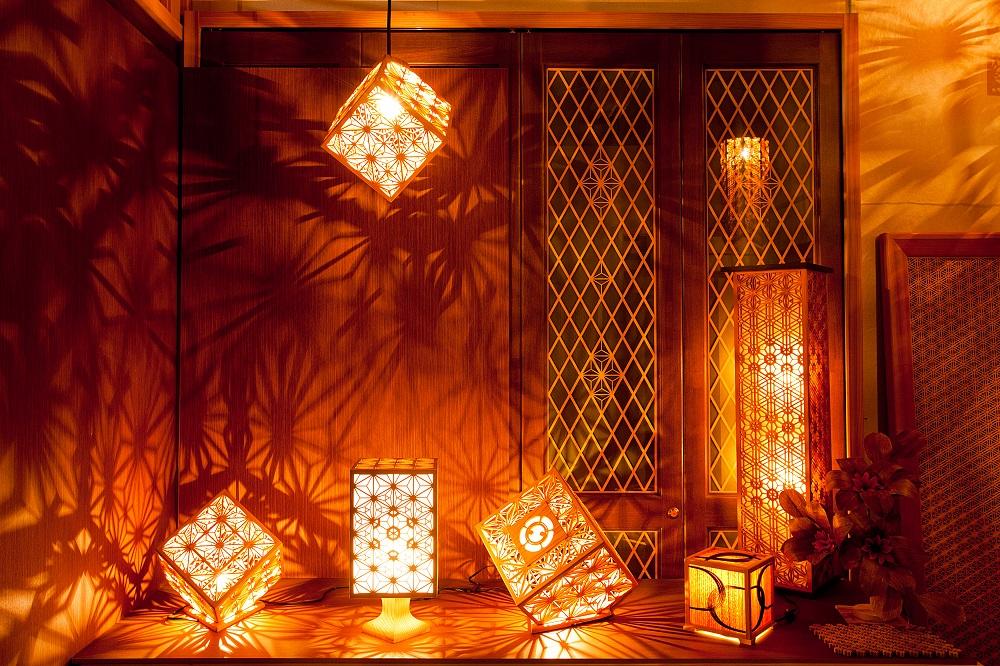

The beauty of light and shadow, Okawa Kumiko

Town where you can rediscover the beauty of Japanese houses

Furniture Town Okawa City

Okawa City in Fukuoka Prefecture boasts the highest production volume of furniture in Japan and is known as the "Town of Furniture. The city has a history of nearly 500 years. The city's long history has produced excellent furniture and fixture craftsmen, who have passed on their advanced skills to the next generation. One of the most notable examples is "Okawa Kumiko," a type of braidwork. It is a traditional technique that shows the aesthetic sense of craftsmen who do not mind manual labor that requires a lot of time and energy.

In the furniture town of Okawa

The Only Kumiko Craftsman

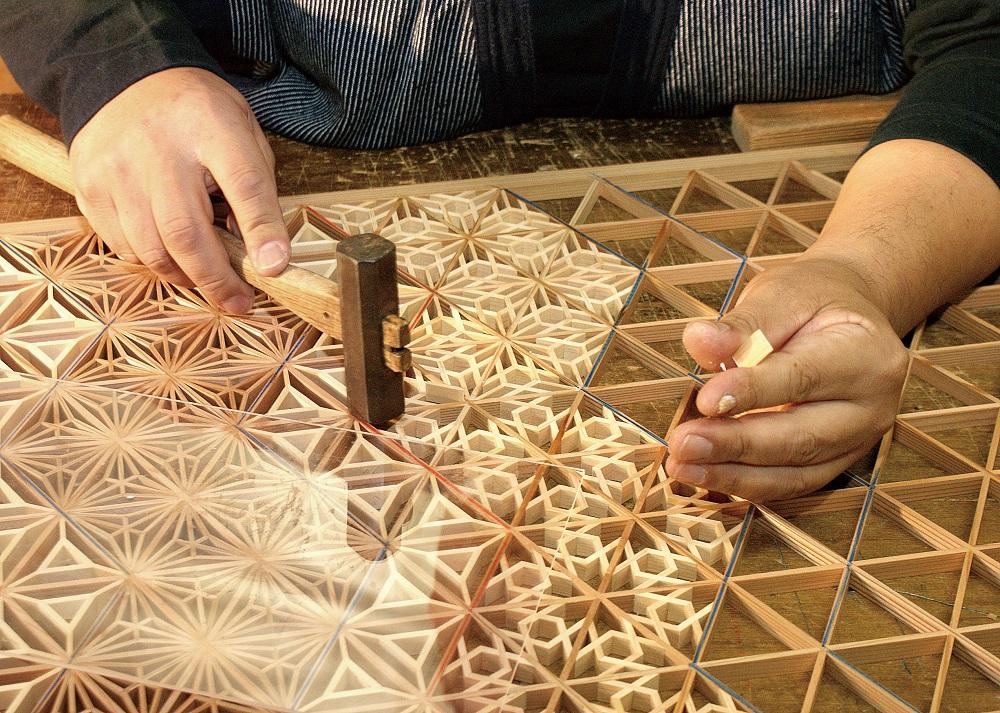

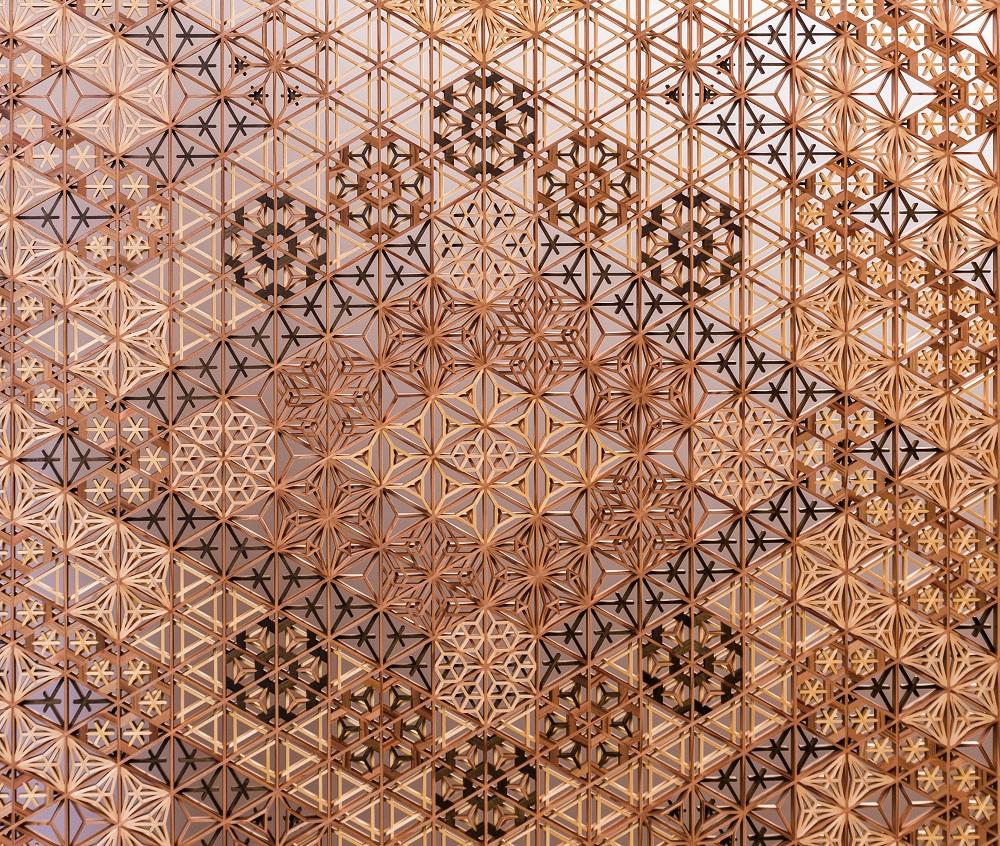

Kumiko is a technique of cutting holes in small pieces of wood and combining them into a geometric pattern without using nails or glue. It is used for fittings such as screens, doors, shoji screens, and transoms. Kumiko work was introduced from China as an architectural technique for shrines and temples in the Asuka Period. It was greatly developed in the Edo period (1603-1867), and more than 200 types of kumiko patterns with botanical and other motifs were created. Kumiko craftsmen existed all over the country, and the craftsmen began to produce Kumiko with their own regional names.

Kumiko began in Okawa City about 300 years ago. Since then, while the number of kumiko craftsmen throughout Japan has been decreasing due to the westernization of the housing environment, the art of kumiko work has been passed down without interruption in Okawa City, a "furniture town. In other places, there are only one or two kumiko craftsmen per prefecture, but in Okawa City, there are many craftsmen who can make kumiko. Therefore, there is an atmosphere of friendly competition and improvement of techniques.

Okawa Kumiko" was especially in the limelight when it was used for the interior of the coaches of JR Kyushu's luxury train "Nanatsuboshi". Mr. Masato Kinoshita of Kinoshita Kigei and others were involved in this project. Mr. Kinoshita is the only craftsman in Okawa City who specializes in the craft of kumiko. In fact, other craftsmen are said to be making braid at the same time as being fittings craftsmen.

His father and brother were also joiners. After graduating from high school, Kinoshita apprenticed himself to a joiner in Kanuma City, Tochigi Prefecture. He says, "Techniques are not something you learn in school. You learn it from the craftsmen. However, it takes at least 10 years to fully master the technique. When I saw my master's real kumiko, I was so impressed that I thought God had made it," he said. This is the starting point of Kinoshita's devotion to his craft.

In delicate exquisiteness

Strength and beauty.

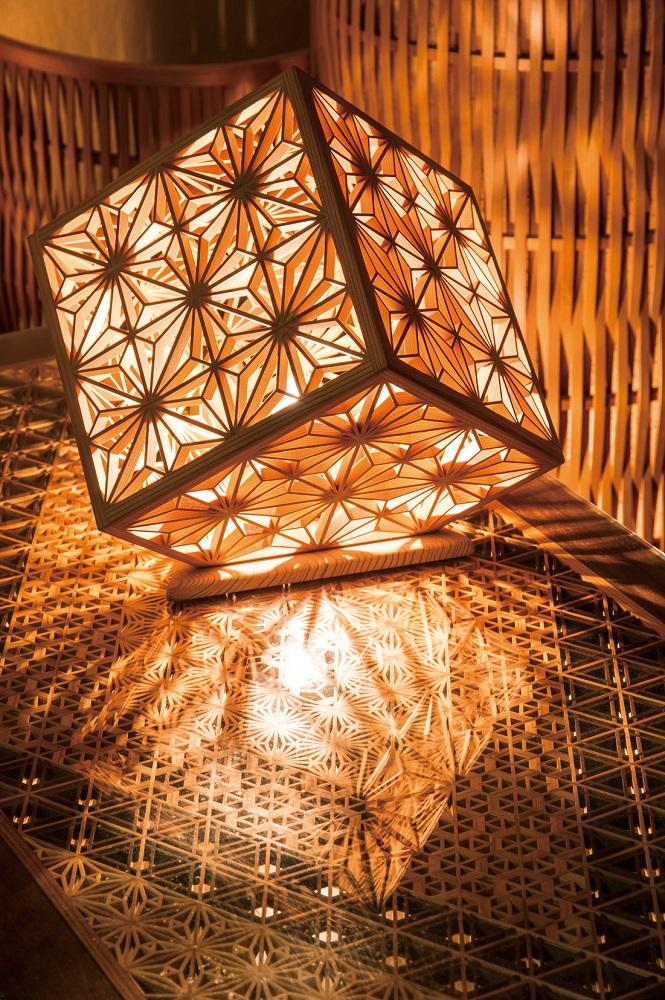

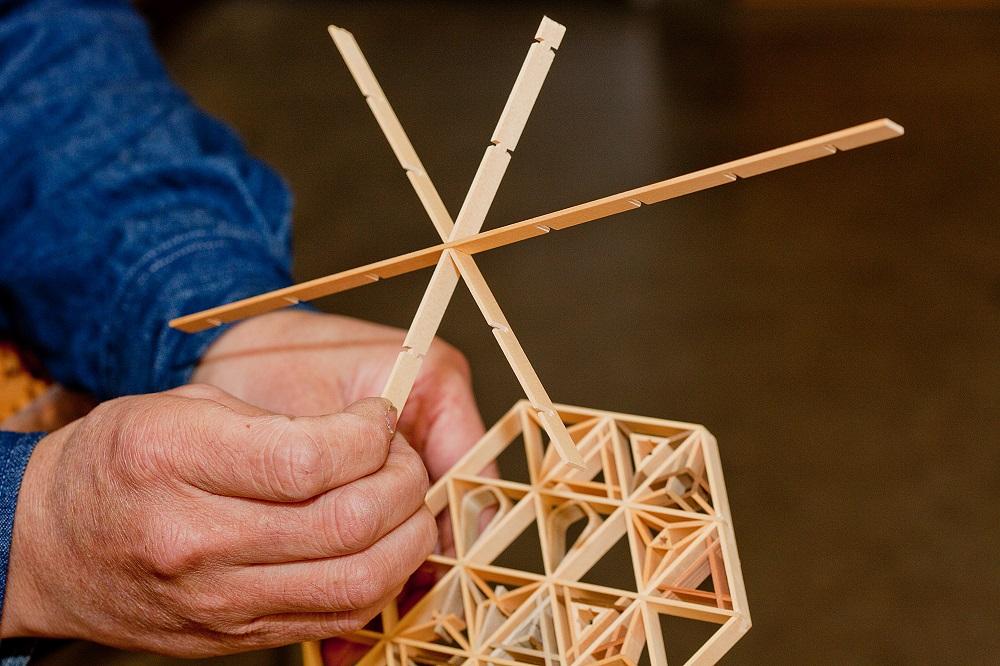

Kumiko work is made by splitting wood such as cypress, cedar, and hiba (Japanese cypress) that has been dried for at least five years into thin strips of about 2 mm or less than 1 mm, and then grooving, drilling, and hosoing the strips at subtle angles. Grooves are cut to 1/100 mm, sometimes 1/1000 mm. This requires many years of intuition on the part of the craftsman. The grooves are then joined one by one with similarly thinly cut members, using planes, saws, chisels, and other tools to adjust the thickness. The design is created by assembling the pieces so that there is not even a paper-thin gap between the pieces. The pieces are assembled from the smallest detail, sometimes in the tens of thousands of pieces. No glue is used.

The resulting braided crafts look delicate but are sturdy enough not to be easily broken. When I said to him that it must be a delicate handwork to make delicate and exquisite Kumiko, he quickly opened one of his hands and showed it to me. A large and sturdy hand. However, there is a core of strength and beauty in his hand. Yes, just like Kumiko work.

While pushing a delicate Kumiko lampshade, he says, "Kumiko is very strong because each piece of wood supports each other. It must be the same thing. For the Natsuhoshi work, he teamed up with nine companies that also work in Okawa, and he proudly states, "We put out the best of Team Okawa's skills.

Kinoshita Mokugei official website

The world of a thousandth of a millimeter.

beautiful graceful pattern of diagonal stripes

Nitahara Fittings Manufacturing is engaged in the production of fittings and braiding. The brothers Man and Shinichi are the second generation, and Shinichi's sons, Tatsuhiro and Shinji, are the second generation. Shinichi's wife, Yuki, also participates in the braid production. It is a rare example of a family with both parents and children passing down the techniques. Shinichi has been certified as an "Okawa no Shokunin" (artisan of Okawa).

There are more than 200 types of kumiko patterns based on the "mitsugumite" pattern, which is a combination of equilateral triangles. These include the "honro-me" pattern used in shrines and temples, the "hemp leaf" pattern used to ward off evil, the "turtle shell" pattern used for good luck, and the "Rubi-hishimanjishi-kuzushi" pattern. The color also varies depending on the wood used. Hiba (hiba) is yellow, cedar brown, magnolia blue, and cypress white. The natural colors add a light touch of color to the kumiko.

Now, the kumiko and carved fittings are made to order and do not remain with the craftsman. Therefore, it is difficult for tourists to see them. Okawa City introduces a workshop tour and a hands-on experience of making kumiko as part of its tourism experience program. And "Nitahara Fittings Factory" accepts general tourists and other visitors to experience the Kumiko making process. Using a small assembly kit, visitors can learn the fascinating process of making kumiko.

The opportunities to see and receive orders for Kumiko work and carved fittings have been drastically reduced as lifestyles have changed and housing has become more westernized. Living in a Japanese house may have been like living in a small museum. I hope that there will be more opportunities to learn about them.

Nitahara Fittings Seisakusho official website

Click here for more information on Okawa Kumiko.

| name | Okawa Traditional Crafts Promotion Association |

|---|---|

| address (e.g. of house) | 483-8 Oaza Gohara, Okawa City, Fukuoka Prefecture (next to Okawa Sangyo Kaikan) |

| phone | 0944-87-0035 |

| Business Hours | 8:30-17:15 |

| regular closing day | Every Saturday, Sunday and national holidays |

| supplementary information | Related URL:. Okawa Traditional Crafts Promotion Association official website |