Kyushu Travel: People, Things, and Things "Hand-pulled Noodles at Higo Sogawa

This is an interview article highlighting "people, things, and goods" that you can encounter on your trip to Kyushu as an opportunity to learn about the good points of each Kyushu region. We will bring you the fascinating Kyushu.

More than 100 noodle mills with PB products alone

It's getting hotter and hotter. It is time to enjoy Soumen (fine white noodles). Speaking of Soumen, Shimabara Soumen is well known in Kyushu, followed by Kanzaki Soumen and Minamiseki Soumen. However, a closer look at the manufacturers of local Soumen and Udon noodles that are often seen at roadside stations reveals the name "Higo Soukawa". In fact, it is a noodle factory in Kosa Town, Kumamoto Prefecture, which boasts more than 100 PB products of Soumen.

It all started with "father's leaving the business" opening.

Higo Sogawa Co. stands in a small rural area. The company has a directly managed restaurant along the national highway, and the factory is located behind the restaurant. Mr. Kensaku Sakamoto, managing director and factory manager, showed us around the factory. The factory manufactures not only hand-pulled somen and udon noodles, but also dried somen, soba noodles, chilled noodles, chilled noodles, "ramen," and pasta. The company has been in business for 32 years, and Mr. Sakamoto is the second generation. It defies the expectations of a long-established business.

Furthermore, the founder and current president, Kenichi, is a former employee of the prefectural government, in other words, a full-fledged public servant. A friend of my father's who ran a noodle factory in Aichi Prefecture built a second factory in Kumamoto. During the bubble era, the high-end hand-pulled somen noodles sold like hotcakes, but the bubble soon ended and the Kumamoto factory had to withdraw. However, the bubble economy soon ended and the Kumamoto factory was forced to withdraw. Kenichi, who was helping his friend, resigned from the prefectural government and started managing a noodle factory.

Hand-rolled manufacturing method born of the wisdom and diligence of the Japanese people

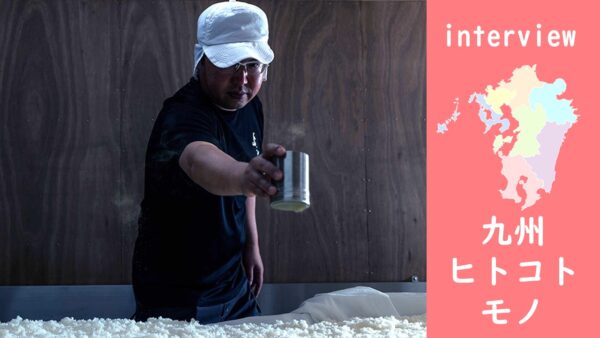

Twenty-five employees work at the factory, with the earliest workday starting at 4:00 a.m. Unlike machine-made noodles, the process of making hand-pulled somen requires many steps and takes two full days to complete. The ingredients for hand-pulled somen noodles are wheat flour, salt, water, and a small amount of vegetable oil and flour to prevent sticking. The ingredients are kneaded together to form a dough, which is then aged to make a "men-tai" (noodle belt), which is then layered to form the base. The dough is then stretched by applying pressure, and the aging process is repeated.

After the repeated stretching and ripening process, the thinly stretched dough is hung in a figure of eight on two tubes. Mr. Sakamoto holds out a piece that is already rolled and says, "Please try to pull it. When I felt it was about to break, he said, "Don't worry, just pull it as hard as you can. The elasticity is like rubber, and it does not break!

By hanging them in a figure-eight pattern, the noodles can be loosened from each other with a stick," he says. The noodles are then matured and pulled repeatedly to ensure that the gluten fibers are uniform and aligned vertically. The gluten's stickiness and elasticity are strengthened, which gives hand-pulled somen noodles their resilient texture and smooth, smooth texture.

After semi-drying, the noodles are left to rest overnight before being dried for the main drying process. The noodles are stretched to a length of 60 cm, and then "kadoboshi" (a machine to dry the noodles) is used to stretch them to about 1.6 meters, and two thin sticks are used to evenly spread the noodles. The noodles are then stretched by hand to about 2 meters in length and dried to complete the process.

Another extra step is the original "Junsei," which is semi-raw noodles. The noodles are dried to 12% moisture content and then moistened with mist and steam in a 95% humidity "moshi moshi room. The shelf life is shorter than that of dried noodles, but the noodles are more matured and the chewy texture is appreciated. This method of making noodles by layering and stretching is unique to Japan. I think it's amazing that the first person thought of this method. He passionately says that the Japanese people's skill in sparing no effort has given birth to hand-pulled somen noodles.

."Finding the Future of Somen Noodles in "Te-nobu" (Hand-pulled noodles)

Now, Kensaku majored in architecture at Tama Art University and worked for an architectural firm in Tokyo. However, about 20 years ago, he returned home after learning of his father's noodle-making business situation. Like his father, he left his job as a salaried worker to run his own noodle-making business. The bubble economy had burst, and people were moving away from expensive hand-pulled somen noodles," said Kensaku. Kensaku asked a senior member of the basketball club at Tama Art University, who ran a design company, for a design concept to be used for Higo Sogawa's packaging. He valued the basic concept and established the Higo Sogawa brand.

While the noodle-making industry is in a difficult situation, Higo Sogawa is betting on survival with a variety of private-brand products made with "hand-pulled" noodles and in collaboration with local specialties. The company's production method is clearly different and clearly tasty. I believe that is where the future lies. If you make delicious noodles, people will know about it. That will become experience to support them.

The directly managed store restaurant offers noodle dishes directly from the factory. There are brightly colored tomato somen noodles, chewy udon noodles, and miso nyumen noodles. Soba, Chinese noodles, pasta, and more can all be enjoyed with the firm flavor and elasticity of hand-pulled noodles.

If you find unique dried noodles kneaded with local specialties at a roadside station or souvenir store on your trip, and the manufacturer is "Higo Sogawa," you can be sure they are delicious noodles.

Higo Sogawa hand-pulled noodles

The company continues to focus on making hand-pulled noodles using traditional methods and carefully selected ingredients.

The secret of their popularity is their willingness to take on the challenge of using their particular hand-pulled manufacturing method for a variety of noodles, including somen, udon, hiyamugi, soba, ramen, chilled Chinese noodles, and five-grain pasta.

| Direct Sales and Eateries | 1670-1, Hendami, Mifune-cho, Kamimashiki-gun, Kumamoto 861-3206, Japan |

Gift items are also popular